How it works - Working Principle of Ammonia Absorption Systems

The technology of absorption refrigeration plants has been used for cooling purposes for over a hundred years now. In plants of today the most modern technology is being used for the design, the components and the control strategy, which, of course, improves the economic value and the reliability of the plants considerably.

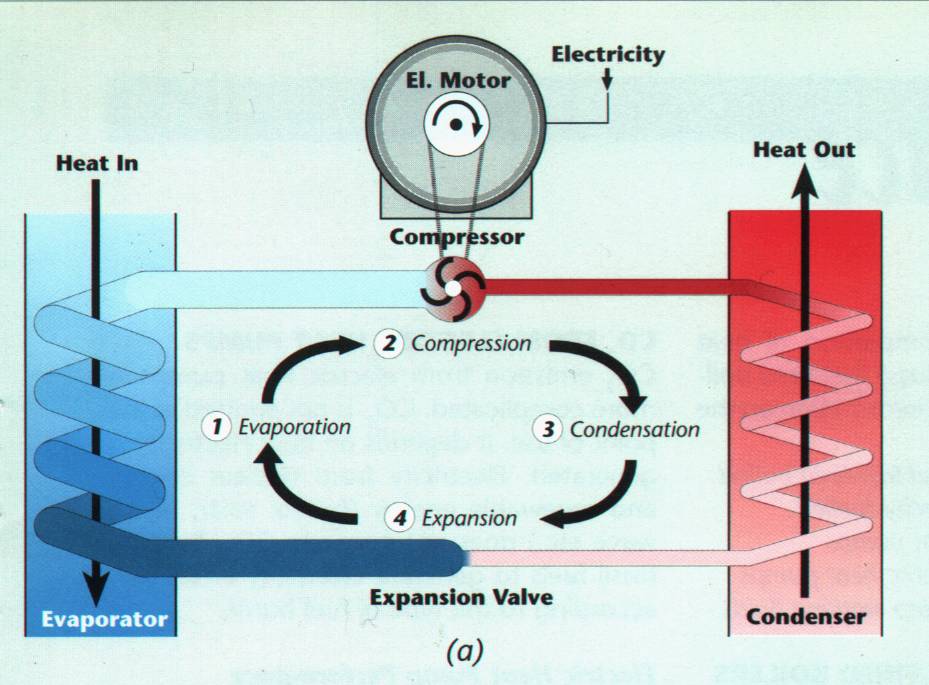

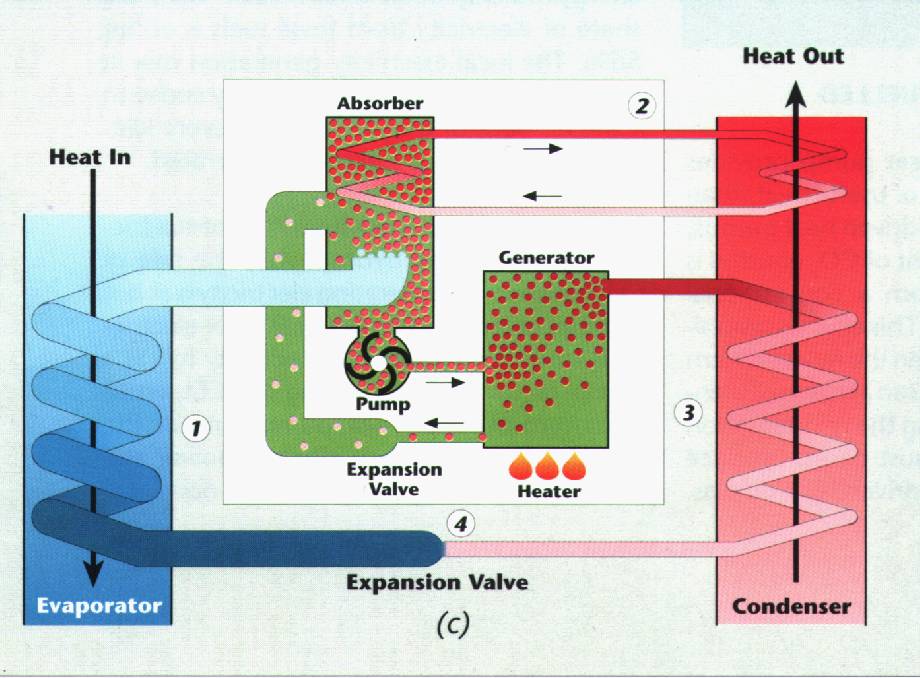

In a cooling machine the refrigerant evaporates at low temperature and low pressure. The vapour is extracted from the evaporator, than transformed to a higher pressure and liquefied in the condenser.

| In a compression refrigeration machine a mechanical compressor is used to take the refrigerant vapour from the lower evaporation pressure to the higher condensation pressure. The condensation heat produced in the condenser is dissipated by means of a cooling tower, while the evaporator produces the refrigeration capacity, taking heat at a low temperature. |  |

| In an Absorption Refrigeration Plants (ARP), this process is realized by means of a solution circuit, which serves as a thermal compressor. A liquid absorbent dissolves the refrigerant vapour. This liquid is pumped to the high-pressure level in the desorber or generator, where the refrigerant is separated again from the liquid solution. This is accomplished by heating up the solution to the boiling point so the refrigerant evaporates out of the solution. This heating can be accomplished by waste heat , steam or by a gas or oil burner. The ammonia vapour is subsequently liquefied in the condenser. The condensation heat, as well as the absorption heat has to be dissipated to the ambience. |  |

The main difference between a compression and an absorption cycle is that the former needs mechanical energy as a driving energy for the compressor and the latter needs thermal energy for the desorber and only a small amount (2% of the driving energy) of electricity for the liquid pump.

In some cases, it is useful to build ARP's with several stages, for instance when the temperature of the driving energy is not high enough (for example when the cooling water of an engine is used) or when cooling is needed at different temperature levels.